We have all been there: standing in the bedding aisle of a department store, staring at a dizzying array of plastic-wrapped sheet sets. Some boast a modest 200 thread count, while others scream 1,000 or even 1,200 in bold, metallic lettering. The price tags often scale right along with those numbers, leading most of us to a simple, logical conclusion—the higher the number, the better the sheet. Right?

As it turns out, that logic is exactly what many manufacturers want you to believe, but it is not entirely accurate. In the world of textiles, thread count has become a powerful marketing tool that often obscures the actual quality of the product. If you have ever bought high-thread-count sheets only to find them scratchy, heavy, or prone to pilling after three washes, you have experienced the thread count myth firsthand. This guide is designed to peel back the layers of marketing jargon and help you understand what actually goes into a high-quality bed linen so you can sleep better every night.

The Basics: What is Thread Count?

At its simplest level, thread count is a measurement of the density of a fabric. Specifically, it is the number of horizontal threads (the “weft”) and vertical threads (the “warp”) woven into one square inch of fabric. For example, if a fabric has 100 threads running lengthwise and 100 threads running widthwise in a single square inch, it is marketed as having a 200 thread count.

Technically, there is a physical limit to how many threads can fit into a square inch. Once you start exceeding 400 or 500 threads, the space becomes incredibly crowded. To go beyond that, manufacturers must use thinner and thinner threads. While thin threads can lead to a very soft, lightweight fabric, they must also be exceptionally strong to avoid breaking. This is where the distinction between quality and quantity begins to blur.

The Marketing Myth of High Thread Counts

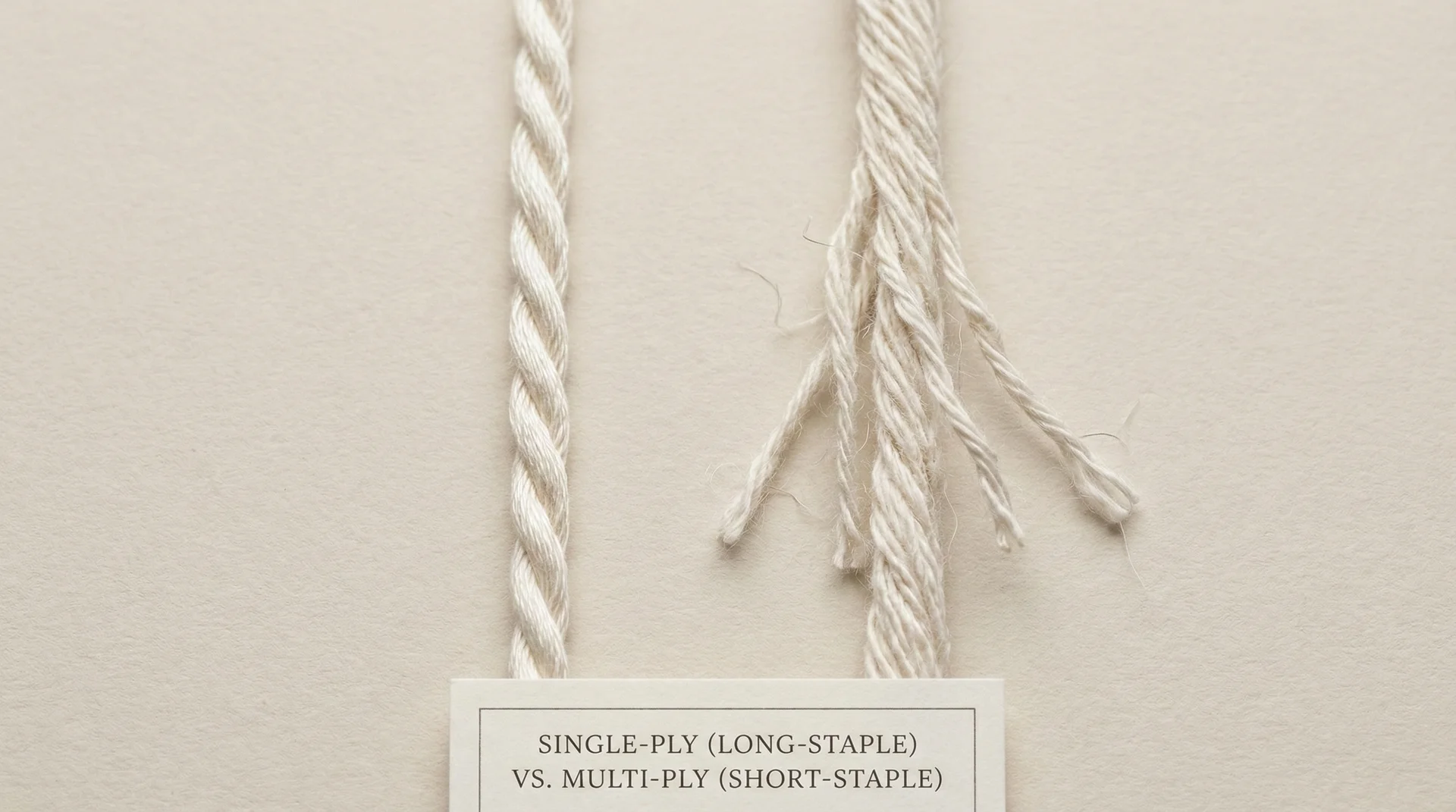

If the physical limit for standard cotton threads is around 500 per square inch, how are brands selling 800, 1,000, or even 1,500 thread count sheets? The answer lies in a technique involving “multi-ply” yarns. A ply refers to the number of individual fibers twisted together to make a single thread. In high-quality linens, manufacturers use “single-ply” yarn, which is made from long, strong fibers twisted together once.

To inflate thread count numbers, some manufacturers use “multi-ply” yarn made from shorter, weaker fibers. They might twist three or four thin, lower-quality fibers together to create one thread. When calculating the thread count, they don’t count the one thread; they count each individual fiber within that thread. So, a 250-thread-count sheet made with 4-ply yarn suddenly becomes a “1,000-thread-count” sheet on the packaging. This is often a red flag. These multi-ply yarns are usually made from cheaper, shorter fibers that are prone to fraying and pilling, resulting in a sheet that feels heavy, doesn’t breathe well, and lacks the longevity of a true high-quality set.

Why Ply Matters

When you are shopping, always look for the word “single-ply.” A 300-thread-count sheet made from single-ply, long-staple cotton will almost always feel softer and last longer than a 1,000-thread-count sheet made from multi-ply yarn. Single-ply construction allows for better airflow, which is essential for temperature regulation while you sleep. Multi-ply sheets tend to be dense and stifling, trapping heat and moisture against your skin.

Fiber Quality: The Real Hero

If thread count isn’t the ultimate indicator of quality, what is? The answer is the fiber itself. Most bed linens are made of cotton, but not all cotton is created equal. The most important factor in cotton quality is the “staple length.” A staple is the individual fiber that makes up a cotton boll. Longer staples are more desirable because they can be spun into finer, stronger, and smoother yarns.

Extra-Long Staple (ELS) cottons, such as Egyptian cotton, Supima, or Pima, are the gold standard. Because the fibers are longer, there are fewer ends exposed when they are spun into yarn. This means the fabric is significantly smoother to the touch and less likely to pill over time. When you buy a sheet made from 100% certified Egyptian cotton, you are paying for the strength and silkiness of the fiber, which is far more important than whether the thread count is 300 or 600.

Common Fiber Types to Know

- Egyptian Cotton: Grown in the unique climate of the Nile River Valley, this cotton produces the longest staples in the world. Look for a certification seal to ensure it’s authentic.

- Supima/Pima Cotton: A high-quality American-grown ELS cotton. It is known for its durability and color retention.

- Linen: Made from the flax plant, linen doesn’t use thread count as a metric. Instead, it is measured by weight (grams per square meter). It is incredibly breathable and gets softer with every wash.

- Bamboo/Lyocell: These are often praised for their moisture-wicking properties and silky feel. Like linen, their quality is more about the processing and weave than the raw thread count.

Understanding Weaves: Percale vs. Sateen

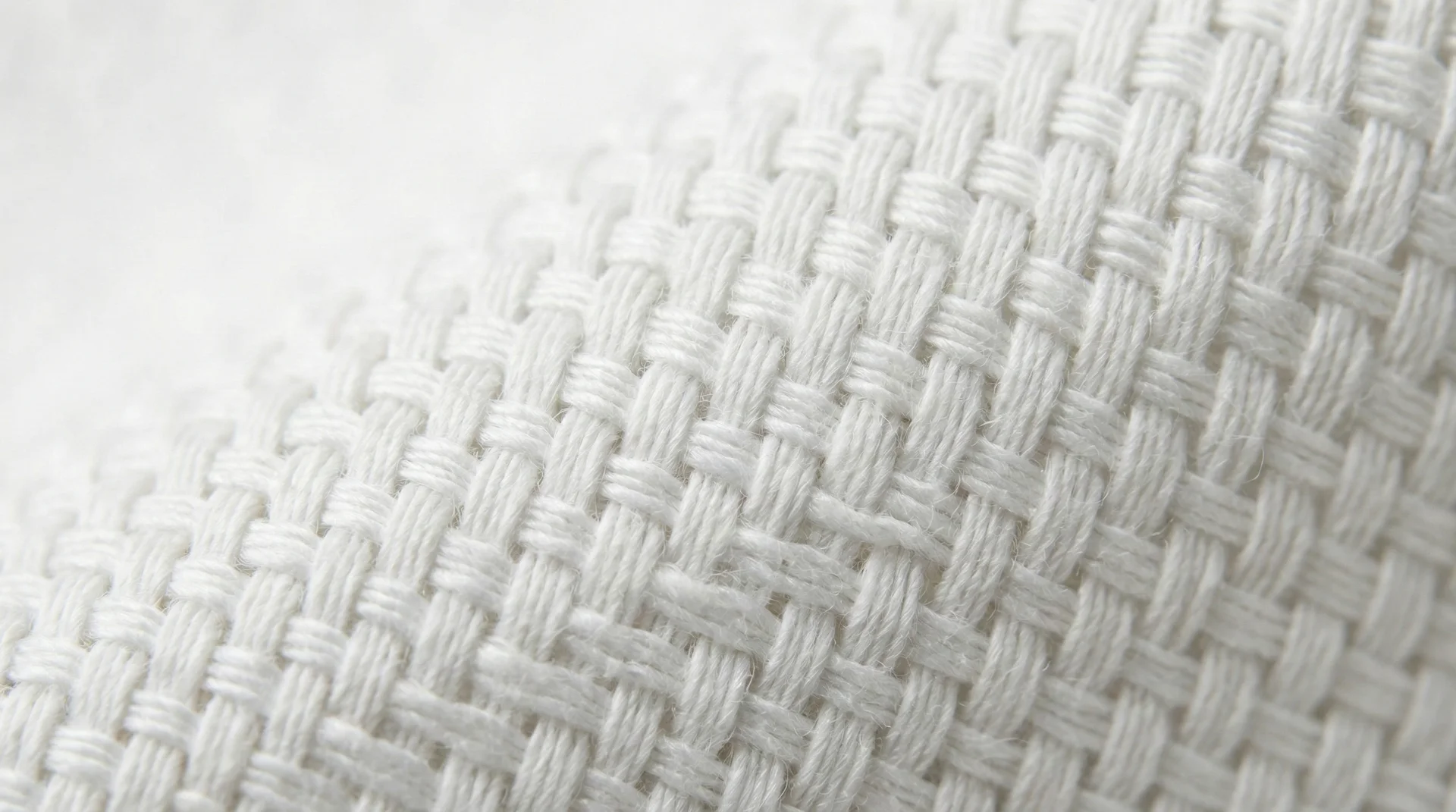

Once you’ve settled on a fiber and a reasonable thread count, the next choice is the weave. The weave refers to how the threads are interlaced, and it drastically changes the feel and performance of the sheets. The two most common weaves are Percale and Sateen.

Percale uses a traditional one-over, one-under weave. This creates a matte finish and a crisp, cool feel often associated with high-end hotel bedding. If you are a “hot sleeper,” percale is your best friend because it is highly breathable. On the other hand, Sateen uses a four-over, one-under weave. This exposes more of the thread surface, creating a subtle sheen and a silky, drape-like feel. Sateen is typically heavier and warmer than percale, making it ideal for cooler climates or those who prefer a snugglier feel.

The Ideal Thread Count Range

So, if more isn’t always better, what is the “sweet spot”? For most high-quality cotton sheets, a thread count between 200 and 400 is ideal. In this range, you get a balance of softness, strength, and breathability. If you see a sheet in the 500 to 600 range that uses genuine single-ply ELS cotton, it will likely be incredibly luxurious and dense, but once you go above 600, you are almost certainly entering the territory of diminishing returns or marketing deception.

For linen, don’t look for a thread count at all. For silk, look for “momme” weight. For flannel, look for weight in ounces. Each material has its own specific measurement of quality, and applying the thread count standard to all of them is a common mistake that leads to poor purchasing decisions.

How to Test Quality In-Person

If you have the opportunity to touch the sheets before buying, ignore the box and use your senses. A high-quality sheet should feel smooth, not waxy or overly stiff (which can be a sign of chemical finishers used to mask low-quality fibers). Hold the fabric up to the light; a good weave should look uniform and tight, without large gaps or irregularities. Finally, check the weight. A quality sheet has a certain “substance” to it without feeling like a heavy canvas.

Caring for Your Linens

Even the finest 400-thread-count Egyptian cotton sheets won’t last if they aren’t cared for properly. High-quality fibers are natural and can be damaged by high heat and harsh chemicals. To extend the life of your bedding, wash your sheets in cool or warm water with a gentle, liquid detergent. Avoid bleach and fabric softeners, as these can break down the fibers and leave a residue that reduces breathability. Tumble dry on low heat or, better yet, line dry them to maintain the integrity of the weave. Proper care ensures that your investment in quality sleep pays off for years to come.

Final Thoughts

In the end, the perfect set of sheets isn’t about the biggest number on the label. It’s about the quality of the fiber, the honesty of the construction, and the type of weave that suits your personal sleep style. By shifting your focus from thread count to material and ply, you can avoid the marketing traps and find linens that truly enhance your rest. Remember: 300 well-made threads will always beat 1,000 poorly-made ones. Sleep well!